Beautiful Plants For Your Interior

With the global chocolate market continuing to grow, the cocoa processing industry is facing new opportunities. From Africa and Southeast Asia to South America, many entrepreneurs and farmers are hoping to increase the value of cocoa and expand their profit margins through localized processing. Among these, cocoa powder, due to its widespread demand and diverse uses, is one of the most promising processed products.

If you are considering starting a cocoa processing business, understanding how cocoa powder made from cocoa beans is the first step. This article will provide you with a comprehensive overview of the processing technology, necessary equipment, cost assessment, and business opportunities to help you launch your cocoa powder production.

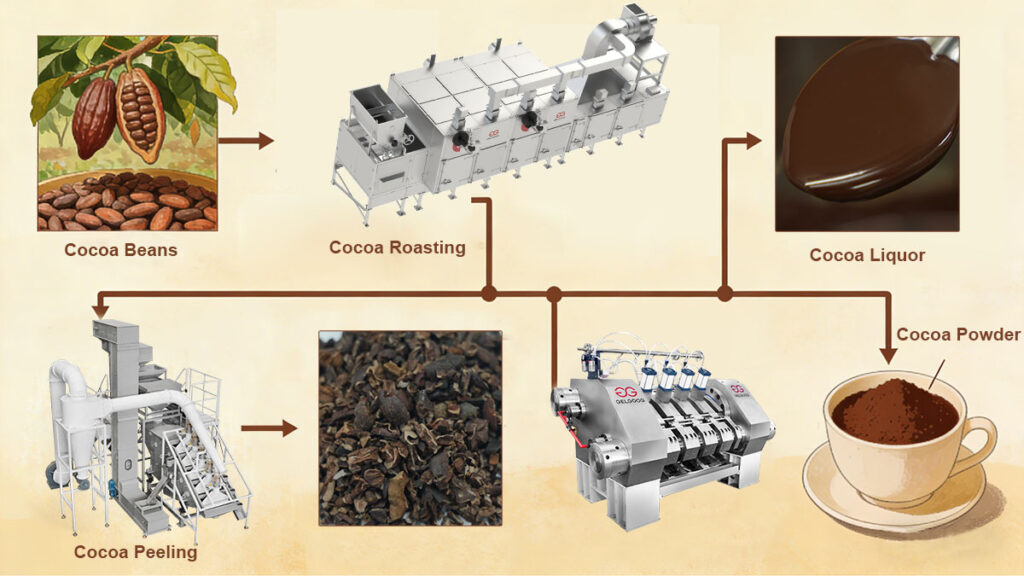

Standard Process for Transforming Cocoa Beans into Cocoa Powder

1. Cocoa Bean Cleaning and Grading: The raw cocoa beans are cleaned to remove impurities (stones, twigs, dust), metal, and then graded (by size and quality) to improve the uniformity of subsequent roasting and product stability.

2. Roasting – The Key to Flavor: Roasting activates the cocoa flavor and is one of the most important steps in the entire process. By controlling temperature and time, the color, flavor intensity, and bitterness of the cocoa powder can be adjusted.

3. Peeling and Winnowing: After roasting, the outer shells of the cocoa beans are removed, leaving only the cocoa nibs.

4. Grinding into Cocoa Liquor: The cocoa nibs are ground using grinding equipment. The fat melts due to the heat, forming a fluid cocoa liquor. The grinding quality determines the fineness of the final cocoa powder.

5. Hydraulic Pressing– Separating Cocoa Butter and Cocoa Cake: The cocoa liquor is pressed under high pressure to separate the natural fat (cocoa butter).

6. Milling and Ultrafine Milling: The cocoa cake is milled into cocoa powder of different fineness (usually 80–200 mesh).

Depending on market demand, it can be made into:

- Natural cocoa powder

- Alkalized cocoa powder (darker color, used for baking)

7. Sieving and Packaging: Finally, sieving ensures uniform particle size, and then it is packaged into

- 25kg bags for industrial use

- 1kg small packages

- Special packaging for baking

At this point, a bag of high-quality cocoa powder is complete

What equipment to start a cocoa powder processing business?

| Process | Equipment |

| Cleaning | Washing machine, impurity removal machine, stone removal machine |

| Baking | Cocoa Beans Roasting Machine |

| Peeling | Cocoa peeling machine |

| Grinding | Cococa butter grinding machine |

| Press | Cocoa butter pressing machine |

| Crushing | Cocoa cake crushing machine, powder grinding machine |

| Screening | Powder screening machine |

| Packing | Automatic powder packing machine |

How to Start Your Cocoa Powder Processing Business?

1. Clearly Define Your Product Positioning

- High-end “natural cocoa powder”

- Baking-grade dark alkalized powder

- Beverage-grade instant cocoa powder

Different positioning determines your processing methods and equipment configuration.

2. Choose the Right Processing Equipment

Select based on your target market and production capacity.

If you are still unsure, I can help you design a suitable production line solution.

3. Establish Quality Standards + Packaging and Branding

Cocoa powder is a food product; hygiene, quality, color, and aroma consistency are core factors for long-term growth.

Processing cocoa powder is not only a technical process but also an opportunity to maximize the value of the cocoa industry.

Whether you are a farmer, a trader, or an entrepreneur looking to invest in food manufacturing, by mastering key processes, selecting suitable equipment, and establishing a reliable quality system, you can successfully launch your own cocoa processing business.